We are not only responsible but also determined to deliver quality products. We have uncompromisingly maintained highest standards of quality control and assurance adhering to the self enunciated SOP’s (Standard Operating Procedures) for efficient and hazard-free operations. We have appointed personnel for monitoring and supervising products at every level of production for consistently delivering quality that’s pleasant in taste and healthy in nature. We adjust and adapt to the changing needs of our customers and remain dedicated in our efforts to serve them to the best of our ability.

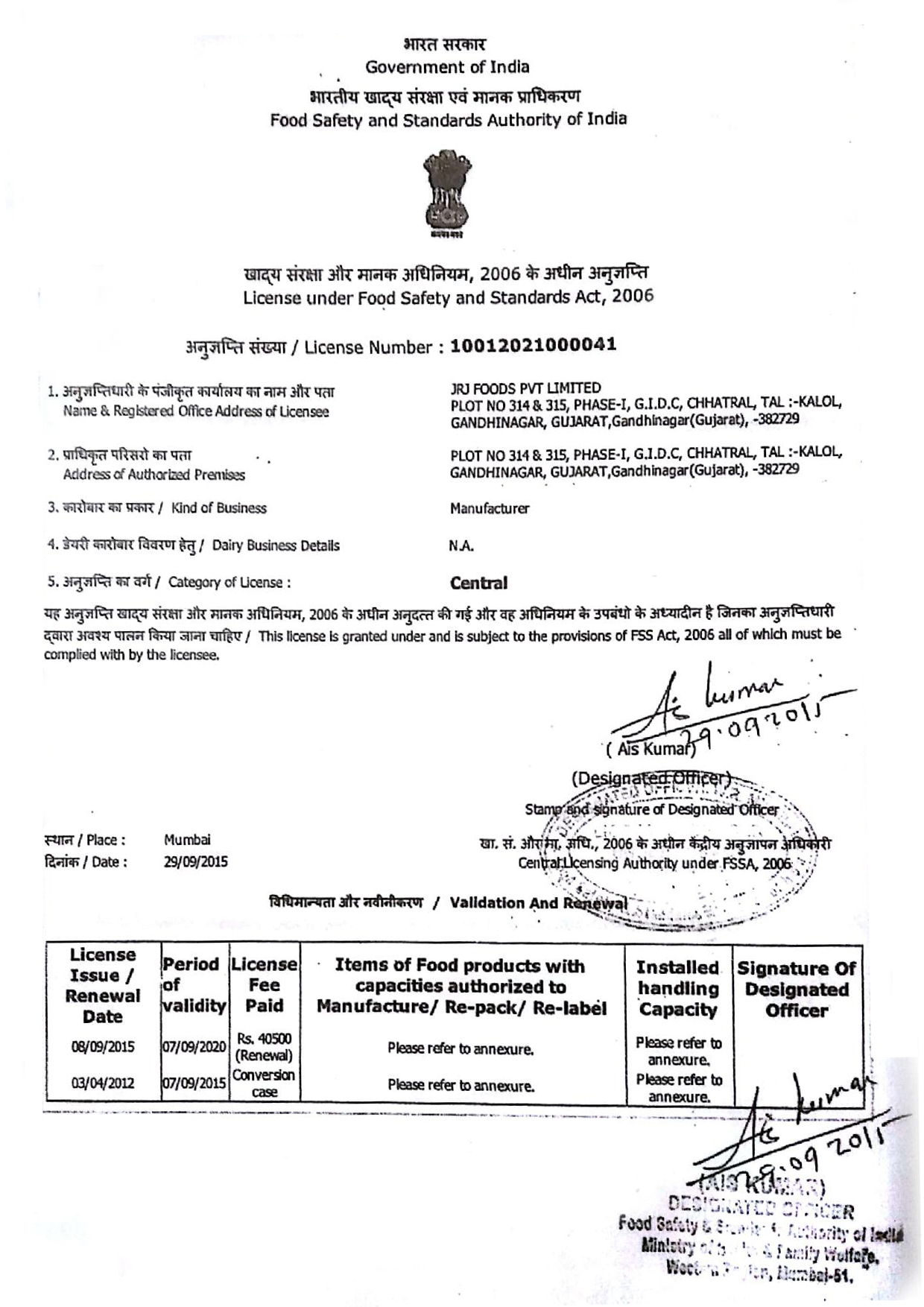

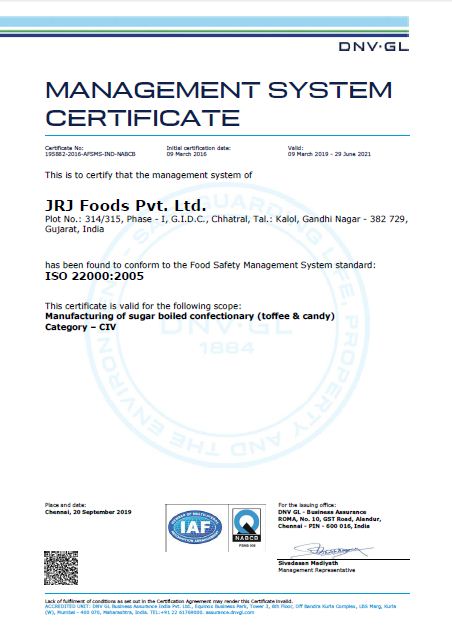

We manufacture our products using only superior quality ingredients, cutting-edge machinery and state-of-the-art technology implementing international quality standard like FSMS (ISO 22000-2005), HACCP, GMP, and GHP, and following regulatory standards like FSSAI, Legal Metrology to ensure that our products are safe and healthy for consumption.

FSMS – Food Safety Management System

FSMS (ISO 22000-2005) is a holistic system of controls to ascertain that quality of food produced is safe for consumption and does not cause adverse health effects. It demands implementation of a variety of food safety norms and standards like GMP, GHP and HACCP.

GMP – Good Manufacturing Practices

It ensures wholesomeness in quality of products at all stages of manufacturing. It implies that methods used in and facilities & controls used for manufacturing, processing, packaging, transportation and storage are in conformity with good manufacturing practices according to Food Safety Policy and HACCP.

GHP – Good Hygienic Practices

GHP is essential for promoting health and controlling spreading of infectious & food borne diseases. A persistent follower of GHP, we export our products to various parts of the world meeting the quality parameters set by CODEX and EIC (Export Inspection Agency).

HACCP – Hazard Analysis Critical Control Point

An internationally accepted methodology and now binding by FSSAI in India, It is a preventative system for food safety that ensures no contamination of any form i.e. Chemical, Physical and Biological hazards.

Cutting-edge Lab For 3 Tire Quality Control

We have also set up a well-equipped analytical laboratory in factory premises for quality testing of Input, processes and output.

When raw material arrives, it is sent for chemical and microbiological testing. Once it passes our rigorous quality check then only it is issued to the production department. At each stage of production, meticulous quality control is exercised by following Internal Process Quality Control (IPQC). Once the final output is ready, it is also evaluated and tested to confirm that it meets high quality standards and is safe for human consumption.

Exercising Experience to Excel Ahead

Working as a contract manufacturing unit of PPPL, first we implemented Quality Circles, Quality Improvement Team (QIT) and Total Quality Management (TQM). From then on drive to consistently improve quality led us to adopt 5S, a Japanese method for workplace organization.

5S represents 5 disciplines for maintaining a visual work place.

1) Seiri (Sort)

keep only essential tools, parts, and supplies while storing or discarding everything else.

2) Seiton (Straighten)

There should be a place for everything and everything must be in its place.

3) Seiso (Shine)

After each shift workplace should be cleaned and everything should be restored back in order.

4) Seiketsu (Standardize)

Standardize refers to maintaining high standards in every work practice and maintaining consistency in their application.

5) Shitsuke (Sustain)

The 5th ‘S’ is regarding maintaining self discipline about consistently following new working style and constructively resolving any issues arising in the process.

We have propagated these systems in our both units and eventually have added other supporting activities like Training, CSR, Visiting employees’ home, Improvement in Infrastructure, Cultural Programmes, Personal Safety Programmes, Food Safety Programmes, Motivational Programmes, Environment Safety, Energy Conservation, Automation, Autonomous Maintenance, Zero Defects, Cost Reduction, and many more.